Record Groups

Research requests may be sent to history@stamfordhistory.org

Research Fees

RG-07

THE STAMFORD MANUFACTURING COMPANY

AND THE STAMFORD EXTRACT MANUFACTURING CO.

“THE COVE MILLS”

Registration Sheet June 1988

Rev. June 1996, Rev. July 1997

Images © Stamford Historical Society

Introduction

In 1791, two millers, William Fitch and John W. Holly built a dam between Stamford and Noroton, trapping the waters of a large cove that extended all the way up to the Country Road, now Route 1. They erected here a tide-water grist mill. Nine years later, they erected a second, larger mill on the west edge of their island-shaped peninsula, cutting a millrace that separated “Cove Island” from the mainland.

Operating serenely for over a generation, the two Holly mills were destined for a far larger place in history.

By 1830 the age of mechanical invention had spawned the Industrial Revolution, most evident in an eruption of giant textile mills. The textile industry, highly dependent on washing, bleaching and dyeing processes, demanded the birth of a parallel industry…a high capacity, scientifically reliable chemical industry...to serve it.

This chemical processing industry was slowly being pieced together. Alum, copperas and sulfuric acid processes were established, as were a few non-textile items such as gunpowder, sugar and glass. Bleaching powder, invented in 1799, quickly spawned one of the largest chemical plants in the world. In 1813 manufacture of soap was put on a scientific basis. Sources for dye-stuffs, however, were still crude and disorganized.

Except for picric yellows and prussian blues all textile dyes were of vegetable or insect origin, many dating back to ancient times. Among the most important of these were the extracts from the heartwood of tropical Haematoxylon trees. Brazilwood, for example, was known early in the old world. Its later discovery on the coast of South America led to the naming of the region. A similar dyewood, campeche or “logwood” was discovered in Central America and used in Spain in the sixteenth century. These two woods produced dark blues, purples or blacks according to the type of mordant and the acidity of the dye vats. Other dyewoods included two species of fustics, yielding yellows, oranges and dark greens, and catechu or cutch from India, Malaya and Burma, yielding rich browns. Sumac leaves were used, and quercitron or black oak bark was used for yellow dyes and tanning.

In 1832, extraction of these dyes was still quite primitive, essentially a grinding and boiling operation. Scrupulous attention to the processing and quality of dyewood extracts was sorely needed. Many of the elements of change were present. Steam power was available. Efficient machinery could be built. The chemistry of dye fixing with iron, aluminum and tin mordants was under study. Certainly the textile market was poised for an enormous increase in the use of these dyes.

Enter two brothers from a family that had two mills in nearby Greenwich and Rye grinding a quinine-containing bark from Peru and other drug items. Henry J. Sanford and John C. Sanford began serious experiments about 1832 in the grinding and processing of dyewoods. They evidently began working soon with John William Hoyt, the aging miller on the Cove, and some of their experiments may have been in Holly's eastern mill. In Nov. 9, 1835 Holly ran an ad in The Sentinel: “Wanted immediately 2 good hands in preparing dyewoods.” At any rate, the Sanfords had focussed on the Cove mills, already converted to steam power and blessed with an excellent harbor in Bishop's Cove to the west of the island. In 1836 they acquired 7/16th interest from Holly. In 1837 they leased all the facilities and set up a stock company capitalized at $50,000 to operate their new venture for processing “dyewoods, dye-stuffs, drugs, spices, plaster, extracts, minerals, clays and paints.”

This was the birth, in Stamford, of an important pioneer in the early chemical industry. The east mill was devoted mostly to drugs such as Peruvian bark. The west mill began a tremendous growth, becoming Stamford's leading industry and the world's foremost source for reliable dyewood extracts. In 1842 after Holly's death, the Sanfords purchased the remaining 9/16th interest for $7,250. They now owned the two mills, land along both sides of Bishop's Cove with wharves, and three dwelling houses. In 1844 the mills started making licorice paste, which had world markets as a laxative and expectorant, as a flavoring in brewing and tobacco, and as a confection which the company sold under the “Triangle S” brand.

That same year the mills were incorporated under the name “Stamford Manufacturing Co.” with Henry J. Sanford as president. The first entry in the minute books (the documents covered by this registration) recorded the Articles of Association, dated Dec. 9, 1844. The population of Stamford was about 4,000.

Capitalized at $50,000, the corporation's assets were mainly in land and buildings. Much of the machinery and some mills in neighboring towns were left in the hands of individual stockholders. Encouraged by success, the company consolidated all these assets in 1847 and recapitalized at $150,000, with each stockholder receiving shares according to his contribution. Its main office was at 189 Maiden Lane in New York.

By 1849, through adding buildings and machinery at a great pace, the directors were able to start paying handsome dividends. Half of the stockholders' investments were returned in the January dividend alone! Within 10 years the investors took out more than four times what they had put in.

Henry J. Sanford, principle founder and 10-year president of Stamford Manufacturing Co., died March 1854 and was succeeded by Rollin Sanford. At this time the assets included the two Cove Mills; smaller mills at Waterside in Stamford, Westport, Port Chester and Rye; one schooner, 10 or more houses mostly along Weed Street, and much technically advanced processing equipment. Landholding included all of Cove Island (the southern areas had been acquired in 1851) and considerable acreage west of Bishop's Cove on the mainland.

A disastrous fire the following year . . . the first of many fires to hit the company . . . destroyed many of the newer buildings at the big west mill; they were of wood. The disaster prompted a rebuilding in the most modern fire-proof masonry, as all hands were put to work getting the plant back on stream quickly. This happened when the Crimean War (1854-6) was giving an unexpected boost. European textile mills reached across the Atlantic to replace disrupted dye-stuff sources and opened large export markets for the mills on the Cove.

In 1859 Rollin Sanford resigned, and control passed to a group of Stamford men headed by Charles H. Leeds, who became president from 1859 to 1870, and Edward F. Leeds, who succeeded his brother until his death in 1878. During the Leeds era, Stamford Manufacturing Co. was Stamford's largest industry and the world's largest dye extract concern. It easily survived the Civil War when shipping was interrupted, though it sold off its mills in Port Chester and Rye. Licorice processing was aggressively pursued.

The company also enjoyed some good years in the processing of barite, a mineral used as pigment and filler in white paints. Starting in the 1840's and 50's as a contract processor of barite ores shipped to Stamford from mines at Cheshire, Conn., the company in 1861 erected a modern dockside mill at Basin Wharf in New Haven. It worked not only Cheshire ores, but also barites imported from abroad as ship's ballast. As the Cheshire mines began to peter out in the 70's, the Stamford company countered by acquiring several mines, purchasing many mineral leases and opening new veins. Mines were also acquired in North Carolina.

The inevitable failure of the barite operations and increasing competition in dyestuffs coinciding with the 1870s' depression clouded the presidency of Edward F. Leeds, but by 1878, when William Gay became president, the company had strengthened and was poised again for prosperity. Its products included various logwood dyes, licorice, flavine (a medicinal antiseptic and dye from black oak bark) and some spices. Prosperity continued through the next presidency (1882) of W. T. Minor, who had married into the Leeds family.

The real impetus for the gilded age of the Stamford Manufacturing Co., however, seemed to be in the energy of William W. Skiddy, Gay's son-in-law. He had joined the concern in 1876, and soon instigated engineering studies and purchases of “leading edge” processing equipment to improve yield and quality both in dyes and licorice. The corporate minutes, for example, contain resolutions to engage consultants in France and Spain to gain information about the advanced processes used in those countries. New cylinders, boilers, extractors, macerators, brew cutters, mullers and vats were installed in fire-resistant brick buildings that, together with mechanized dock facilities dwarfed the earlier mill. Stronger sources for Virginia oak bark and West Indies dyewood were set up. Licorice farms in Turkey, Syria, Spain and Russia were obtained and factories were built. Last but not least, full-time traveling salesmen were hired.

in 1885 an affiliated company, Cove Transportation Company, was set up with four schooners to handle some of the mill's shipping. Earlier transportation had been by small schooners and wagons. Then barges were run to and from New York docks. The barges were often cut-down 4-masted schooners, handled by Cove Transportation Company's steam lighter Pierre C. Van Wyck. Later the harbor was deepened to accommodate direct delivery from deep sea brigantines, barkentines and even large three- and four-masted schooners from Central America and the West Indies, even from as far away as Turkey and Argentina. In 1885, 15 million pounds of licorice root alone had arrived in the very active harbor in Bishop's Cove!

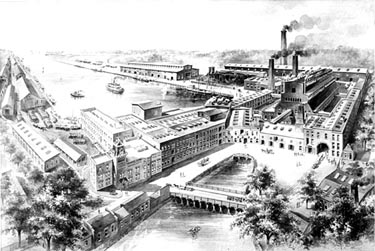

it was foreordained that William W. Skiddy succeed to the presidency. He did in 1889 and the Stamford Manufacturing company entered its peak decade. In the early 1890's a handsome birds-eye view of the west mill shows an astounding complex of “modern” mill buildings two or three stories high, with attendant machine shops, boiler rooms, repair shops, a large brick office building, warehouses, coal elevators and several thousand feet of wharves all laced together on nearly 70 acres by a narrow-gauge railway, and dominated by three huge smoking chimneys, one 126 ft. tall. The company was valued at $2,000,000 in 1900. Chemical and consulting services were offered to customers.

Skiddy, architect of the mill's growth, suddenly found himself in a rear-guard action against irreversible forces. By 1900 some set-backs had already occurred. New sources for logwood and fustic in Honduras and Mexico were beset by the Spanish American War and by jungle transportation problems. A new mill in Lynchburg, Virginia for processing quercitron bark was destroyed by fire in 1897. A fire in 1894 had razed the century-old Holly grist mill beside the Cove dam.

Demand for licorice had run its course, leading to severe losses and the sale in 1902 of the licorice inventory, farmlands and factory in Turkey, in turn rendering the Stamford licorice machinery useless. Half the mill was closed. At the same time, markets for wood dye extracts were decimated by new aniline dyes whose bright colors and fade resistance were taking over the whole industry. It was said for many years, however, that the richest, most beautiful black silks were produced with Stamford logwood dyes. In other bad news, the Lynchburg, Va. black oak mill had to be dismantled because the market for its yellow dyes evaporated.

The Stamford Manufacturing Co. slowed its decline by introducing new dyes using quebracho (axe-breaker) wood and bark from Argentina. Principal markets were in leather tanning and in yellow to brown dyes. Unfortunately, even this market slumped during the panic of 1907. The move merely served to reveal that the directors had chosen to cling to their mill and their raw materials rather than invest in the new chemistry of dyes.

The years of World War I were hardest of all. Sea transportation was virtually cut off. By 1917 a reorganization of the heavily mortgaged, failing company was necessary. General Skiddy, who by this time had acquired 92.8% of the outstanding stock of Stamford Manufacturing Co., joined with three New York business men in organizing a new company named The Stamford Extract Manufacturing Co. This company bought all the factory buildings, land, machinery and houses of the Cove Mills, but within months transferred all the real estate to a Skiddy holding company on a lease-back arrangement. Trade advertising now said simply: “Manufacturers of all kinds of Dyewood and Tanning Extracts. Importers of Chemicals and Dyestuffs. New York office 82 and 88 Wall St.” The president's review of the year 1918 sounded like a company that was barely hanging on.

Within weeks the struggle ended. At 7:00 in the evening of February 19, 1919, the sprawling Cove Mills complex was almost totally destroyed by a spectacular fire fanned by a strong northwest wind. Though the business continued in a small way, the plant was not rebuilt. Amid the firebrands and flames and fantastic bursts of exotic colors there died a company that had been a major force in the birth and early growth of the vast chemical industry…in the end indifferent to the industry's true course.

Robert D. Towne

Stamford Historical Society

June 1988

Rev. June 1996,

July 1997

Bibliography

Principal Sources

Majdalany, Jeanne. The History of the Cove in Stamford, Connecticut. Stamford: The Stamford Historical Society, Inc. 1979. The Stamford Manufacturing Co. and The Stamford Extract Manufacturing Co. Collection. Stamford Historical Society RG - 7. 1844-1920.

Others

Clow, A. and N. L. The Chemical Industry: Interaction with the Industrial Revolution. A History of Technology, Vol. IV, pg 233. London: Oxford. 1958.

Clow, Archibald. The Chemical Revolution. London. (Ferguson No. 660.09)

Davidson's Textile "Blue Book," 15th Ed., 1902, pg 420; 31st Ed., 1918, pg 830. New York: Davidson Publishing Co.

Feinstein, Estelle. Stamford in the Gilded Age. 1868-1893. Pgs 5, 32, 38, 51, 58, 92, 204, 207, 216. Stamford: Stamford Historical Society. 1973.

Feinstein, Estelle, and Pendery, Joyce S. Stamford: An Illustrated History. Woodland Hills, CA: Windsor Publications, Inc. 1984.

Fritts, C.E. The Barite Mines of Cheshire. 1963.

Gillespie, Edward. Picturesque Stamford 1641-1892. Stamford: Gillespie Brothers.

Holmyard, E. J. Dyestuffs in the Nineteenth Century. A History of Technology, Vol. V, Ch. 12. London: Oxford University Press. 1958.

Huntington, E. B. History of Stamford 1641-1868. Pgs 7, 257, 402, 452-2. Reprint Harrison, N.Y. Harbor Hill Books. Orig. 1868, Reprint 1979.

Lobozza, Carl. Stamford, Conn.: Pictures From the Past. Stamford: Stamford Historical Society. 1970.

Pershing, George. Old Stamford Town. Stamford: 1958-1962 [Collection of Newspaper Articles]

Scofield, Edward C. Story of the Cove. The Stamford Historian. Vol. 1, No. 2, Pgs. 147-149, Stamford: The Stamford Historical Society. 1957. Stamford, Conn.

Bicentennial Committee. Stamford Past and Present: 1641-1926. Pgs 74-5. Stamford: Stamford Bicentennial Committee. 1976.

Swan, Herbert. Plan of a Metropolitan Suburb. Pgs 91-3. 1929.

Updegraff Marie. It Happened Here. Stamford Advocate 1966-67. (Collection of Advocate Columns)

List of Records, 1 Box

| The Stamford Manufacturing Co |

| Minutes, Book I |

December 9, 1844 - December 1880. |

Donor: Mr. William S. Payson, 1979, P347-9. 291 pgs., marbleized covers, 3/4 leather binding. H: 33 cm W: 21.5 cm D: 3 cm |

| Minutes, Book II |

January 8, 1881 - July 29, 1899. |

Donor: Mr. William S. Payson, 1979. P347-10. 294 pgs., marbleized covers, 3/4 leather binding. H: 33 cm W: 22 cm D: 4 cm |

| Minutes, Book III |

November 11, 1899 - September 24, 1917. |

Includes by-laws. Donor: Mr. William S. Payson, 1979. P347-11. [300 pages] 283 pgs., black cloth covers, 3/4 leather binding. H: 33 cm W: 22 cm D: 4 cm |

| Log Book |

June 1, 1916 - February 20, 1919. |

For tugboat Runabout operated by Stamford Manufacturing Company et. al: Donor: City of Stamford, 1971. C581p-5. Not paginated. H: 17.5 cm W: 10 cm D: 4 cm |

Time Book

and Pay-Roll Ledger |

February 10, 1923 - January 7, 1928. |

Donor: City of Stamford, 1974. C581p-8a. Not paginated. H: 35 cm W: 21.5 cm D: 1 cm. Lists names of individuals on the payroll and their wages. Primarily the wages were on behalf of the Cove Investment & Improvement Company, the Skiddy-led land-holding company spun off from Stamford Manufacturing Co., though many employees are listed in the Stamford directory as being employees of Stamford Manufacturing Co. |

| The Stamford Extract Manufacturing Co. |

| Minutes, Book IV |

September 4, 1917 - September 3, 1920. |

Donor: Mr. William S. Payson, 1979. P347-12. Loose-leaf binder, black leather covers. H: 29 cm W: 24 cm D: 3 cm [not paginated] |

Mill Photos

Famous Cove Mills Perish in Stamford's Biggest Fire (SHS Newsletter)

back to top

Record Groups